Transform your manufacturing operations with next-generation connected technologies designed for the factories of tomorrow.

Complete IIoT Ecosystem for Modern Manufacturing

Our integrated suite of Industrial Internet of Things solutions delivers comprehensive visibility and control across your entire operation. Each component works seamlessly together whilst providing powerful standalone functionality to address specific operational challenges.

Each solution can be deployed independently or as part of our comprehensive platform, offering flexibility to match your digital transformation strategy.

Anticipate equipment failures before they occur through advanced analytics and machine learning algorithms.

Monitor critical parameters in real-time to ensure optimal equipment performance and longevity.

Track fluid levels remotely across distributed assets with wireless sensors and automated alerts.

Safeguard sensitive equipment by continuously measuring electrical parameters and detecting anomalies.

Seamlessly connect legacy industrial equipment to modern networks without disruptive replacements.

Gain unprecedented visibility into workflow with real-time location and status monitoring of materials.

Predictive Maintenance: Prevent Failures Before They Happen

Our predictive maintenance solution utilises sophisticated machine learning algorithms to identify subtle patterns in equipment behaviour that precede failures. By continuously analysing multiple data streams from your machinery, the system learns what ‘normal’ looks like—and can alert you when conditions begin to deteriorate.

Key Advantages:

Identify potential failures weeks in advance, allowing maintenance to be scheduled during planned production breaks.

Address issues before they cause catastrophic damage, significantly extending the operational life of capital equipment.

For a mid-sized manufacturing plant, predictive maintenance typically delivers seven-figure cost reductions.

Machine Health Monitoring: Real-Time Performance Insights

Key Advantages:

Our system deploys industrial-grade sensors that continuously monitor critical parameters including:

Ruggedised edge computing devices process raw sensor data at source:

Intuitive visualisation platform providing:

Fuel & Tank Level Monitoring: End-to-End Fluid Management

Our advanced fluid monitoring system provides precise, real-time measurement of liquid levels in tanks, vessels and containers across distributed industrial sites. The solution combines highly accurate ultrasonic or pressure-based sensors with long-range, low-power wireless connectivity to deliver continuous visibility of critical fluids.

The system leverages LoRaWAN and NB-IoT connectivity options, providing 5+ years of battery life with hourly reporting intervals. Intrinsically safe options are available for hazardous environments (ATEX Zone 0/1/2).

Measure

Transmit

Process

Predict

Alert

ROI Case Study: Distribution Centre

A regional distribution centre with 12 fleet refuelling tanks implemented our solution, resulting in:

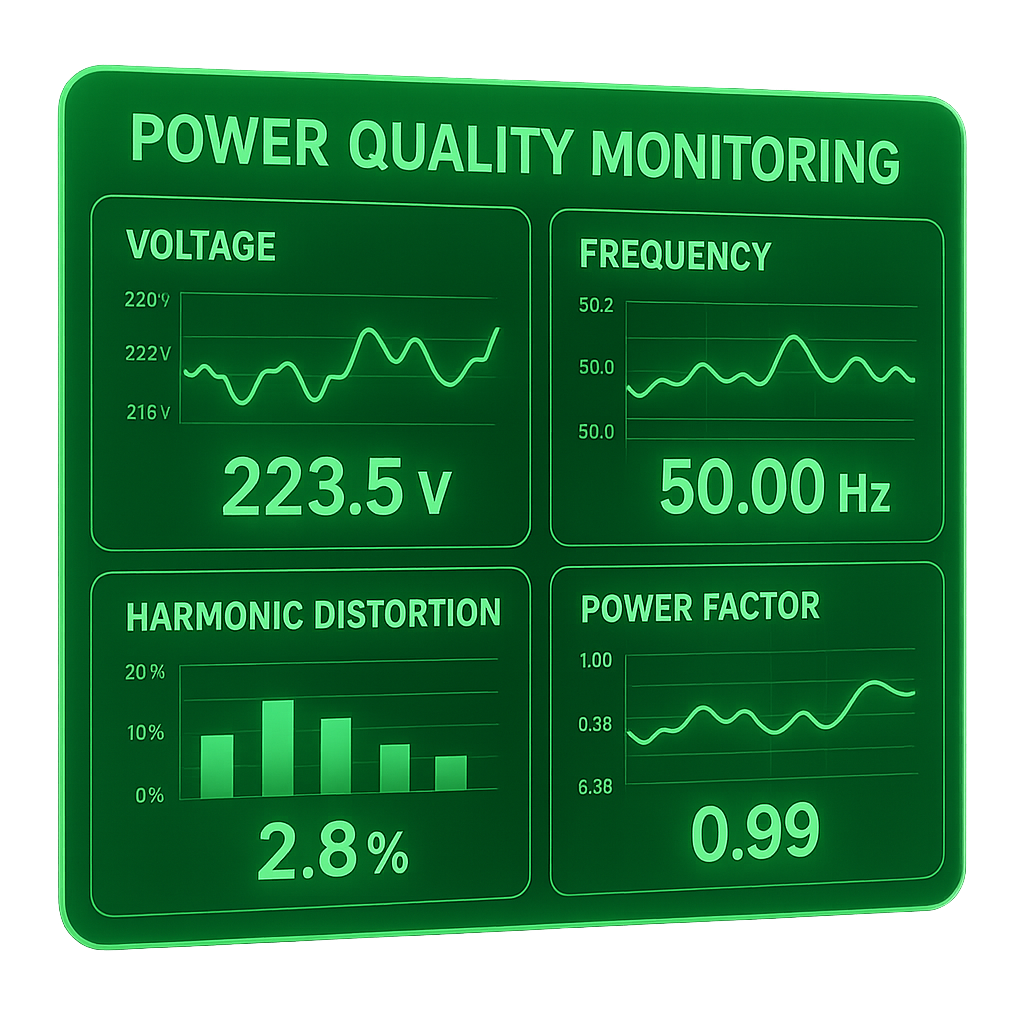

Power Quality Monitoring: Safeguarding Critical Operations

Electrical power anomalies represent one of the leading causes of unexpected equipment failures and production disruptions. Our power quality monitoring solution provides comprehensive visibility into your electrical distribution system, capturing microsecond-level events that traditional systems miss.

Continuous monitoring of voltage, current, frequency, harmonics, transients, and power factor across all phases

Advanced analytics engine identifies patterns, correlates events with equipment behaviour, and benchmarks against standards

Real-time notifications of deviations from acceptable parameters, with severity classifications and recommended actions

Automated response capabilities including selective load shedding, switchover to conditioning systems, and equipment isolation

The system complies with IEC 61000-4-30 Class A measurement standards and integrates with building management systems via BACnet, Modbus TCP/IP, and REST API interfaces. An optional battery backup ensures continuous monitoring during power events.

Power quality issues cost UK manufacturers an estimated £14 billion annually in damaged equipment, scrapped production, and process disruptions.

Modbus/PLC Integration: Modernise Without Replacement

Legacy automation systems represent massive capital investments that often perform their core functions reliably for decades. Our Modbus/PLC integration platform bridges these existing systems with modern IIoT capabilities, extracting valuable data without disruptive replacements.

Our industrial gateways connect directly to existing PLCs, RTUs, and controllers via RS-232/485, Ethernet, or proprietary interfaces. Support includes Modbus RTU/TCP, Siemens S7, Allen Bradley, Omron, Mitsubishi, and dozens more protocols.

Edge computing capabilities perform protocol translation, data normalisation, and initial processing. The system can poll registers at configurable intervals or operate in change-of-value mode to minimise network traffic.

All data is encrypted using TLS 1.3 with certificate-based authentication. Unidirectional communication options prevent any possibility of external control signals reaching critical systems.

Previously isolated data becomes available for advanced analytics, unlocking insights about process efficiency, quality factors, and production optimisation that were impossible with siloed legacy systems.

Production Line Tracking: Complete Workflow Visibility

Our production tracking system provides real-time visibility into material flow, work-in-progress status, and resource utilisation across your manufacturing operation. By combining multiple tracking technologies with powerful analytics, the system delivers unprecedented insights into production efficiency.

Implementation Approach

Our rapid deployment methodology delivers initial results within 4-6 weeks, with a phased rollout approach that prioritises high-impact areas first. The modular architecture allows for gradual expansion without disrupting existing operations.

The system integrates with ERP and MES platforms including SAP, Oracle, Epicor, and Plex to provide closed-loop verification of production orders. Machine learning algorithms continuously refine production forecasts, reducing schedule variance by typically 34-42% within six months of deployment.

Smart HSE Management Using IoT and AI

Transforming health, safety, and environmental management through

intelligent technology solutions for industrial and commercial operations.

Current challenges in industrial HSE management and the transformative potential of IoT and AI technologies

Integrated IoT sensors, AI systems, and smart devices that form our complete HSE management ecosystem

Technical implementation across various industrial sectors with

seamless integration into existing operations

Quantifiable advantages for safety, compliance, and operational

efficiency with clear adoption pathways

Our presentation demonstrates how integrated IoT and AI technologies are revolutionising

HSE management, creating safer workplaces whilst enhancing operational efficiency and environmental compliance.

Smart IoT Solutions for Offshore & Onshore Oil & Gas Operations

The oil and gas industry faces unprecedented challenges that demand innovative solutions:

Hazardous environments demand constant vigilance to protect workers and assets in potentially explosive atmospheres.

Manual processes and legacy systems create bottlenecks, increasing costs and limiting productivity.

Increasingly stringent regulations require precise monitoring and documentation of emissions and potential leaks.

Dispersed operations across challenging terrains complicate maintenance and oversight efforts.

Your ideas matter. Share your requirements and receive a quote crafted just for you.

Ready to Innovate Together?

Get the Quote Now!